There are over 30-million electric vehicles (EV) on the road worldwide today, which is over 5-times of EVs in 2018, and this exponential growth is bound to continue driven by net-zero targets.

The world-wide Net-Zero movement has resulted in the proliferation of electric vehicles (EVs) and the increasing integration of battery energy storage systems across various sectors. In order to truely achieve Net-zero targets through the adoption of battery technology across industries, it’s crucial to ensure the sustainability of the battery technology itself. And, the problem is not the absence of recycling plants or e-waste aggregators but…

The Missing Piece: of the puzzle is the lack of effective tools for assessing Battery Health and determine it’s current market value !!!

BatteryScope tool.

We have a warehouse of fully characterized cells (new as well as recycled) which we offer to battery pack developers through ourDigital/Physical Twinning service while ensuring strict cell uniformity. The recycled cells from our warehouse are an absolute bargain for the second-life applications like battery energy storage and they come with fully tracable characterization data giving you a peace of mind. Every cell in our warehouse has been thoroughly characterized using our state-of-the-art CellScope tool, which combines a multitudes of techniques to asses the cell health.

Battery SoH tools can transform the whole battery ecosystem !!!

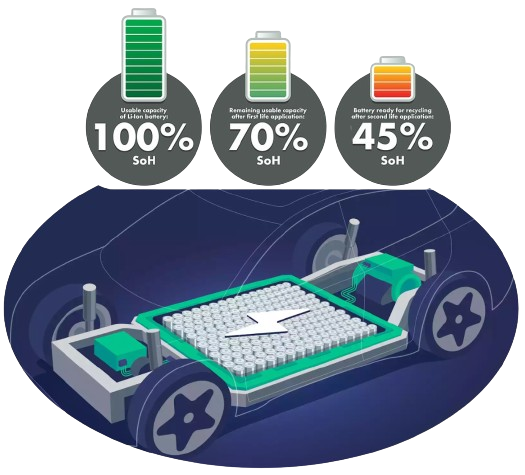

The battery SoH (State-of-Health) monitoring is going to play a crucial role in managing the life-time of a battery optimally. Any improvement in this technology will result in the dramatic betterment of the whole battery ecosystem, for example, this will lead to better predictive maintenance and more informed warranty policies in the energy storage sector, better management of battery assets in the battery swapping industry in the electric vehicle space, better assessment of the end-of-life or second-life of the batteries, better load-balancing by the BMS in the charging-discharging process, better understanding of the impact of rapid charging solutions on the battery health, better predictive managment of thermal-runaway issues in the electric vehicles and battery storage sector. Battery SoH monitoring is crucial in managing the life-time of a battery optimally and it’s an essential need across the whole battery ecosystem.Battery SoH is a Complex Multidisciplinary Science

Battery SoH estimation involves advance multidisciplinary scientific understanding involving chemistry, physics, electrical engineering, computational modelling, machine learning etc. Further, it’s not just a computational exercise but it involves bespoke data collection experimentally for the system under consideration. Due to this complexity, the current SoH market lacks precision, intrepratability and standardization as this is mostly implemented by vendors for their own purpose with limited scientific understanding and experimental data collection.What We do?

ThinkClock Battery Labs is an R&D driven company offering Battery prototyping service powered by Digital Twins to the Battery pack developers enabling rapid prototyping and characterization for any climatic condition. We generate indept Battery Health Analytics using Digital Twins and Spectroscopy techniques namely EIS (Electrochemical Impedance Spectroscopy), Acoustic/RF Spectroscopy, Thermal scanning etc. We reveal the interpretable diagnostic insight about the battery health while relating the microscopic data of the battery with the observable system level behaviour with the help of the models based on Physics and Machine Learning using ourWe have a warehouse of fully characterized cells (new as well as recycled) which we offer to battery pack developers through our

About CEO, ThinkClock Battery Labs

Babu Devnarayan has over 15-years of R&D experience spanning across Academia (Imperial College London, IIIT Allahabad, India) and Industry in the UK ( Rolls-Royce Aerospace , Cobham, Ultra CSS, Trelleborg Offshore, Xtract One etc.). His current expertise is focused on Data-driven modelling of complex physical systems (such as batteries), creating digital twins by combining Physics-based models with Machine Learning, developing

soft-sensors for Battery Health Monitoring with low-cost hardware while exploiting the digital-twins, Spectroscopic techniques for non-invasive sensing. He has a proven track record of conceptualizing high-impact novel technologies and successfully taking them to field deployments. While working at Xtract One Technologies, he has transformed a questionable academic concept into a field-deployable flagship product for the company related to Concealed Weapons Detection using RF Spectroscopy within a year.

One of his patented invention: CogniSense (related to Machine monitoring using RF Spectroscopy) from his PhD research at Imperial College London (one of the top-10 universities in the world) has resulted in a spinout in 2017. It was awarded £200,000 of funding by the Technology Transfer Office of Imperial College based on its novelty and commercial potential.

He is an alumnus of Entrepreneur First (LD10 batch), which is a globally renowned startup accelerator.

About COO, ThinkClock Battery Labs

Ajith Muthayil is a seasoned product strategy expert and business leader with over 17 years of global experience in driving innovation, operational excellence, and sustainable technology solutions. As Co-founder and Chief Operating Officer at ThinkClock Battery Labs, he leads the company's operations, strategic growth, commercialization, customer development and partnerships, shaping the future of battery health analytics and clean mobility.

Ajith previously served as Global Product Manager at Johnson Controls , where he successfully led multiple £10M+ programs for EN54-approved Fire Detection Panels and Loop Devices. His leadership spanned across several countries, managing diverse cross-functional teams and aligning R&D with commercialization to deliver complex, regulatory-compliant products at scale.

An Electronics and Communications Engineer by profession and training, Ajith also holds an MBA from the University of Westminster, London . Ajith excels at bridging the gap between research and commercialization, with a deep commitment to sustainable innovation. At ThinkClock, he is at the forefront of delivering BatteryScope to customers —a next-generation Battery Health Analytics as a Service (HaaS) platform designed to revolutionize battery characterization, monitoring and lifecycle management.

A champion of responsible tech and net-zero progress, Ajith is dedicated to forging global partnerships and driving ThinkClock's mission to power a more sustainable, data-driven battery ecosystem.